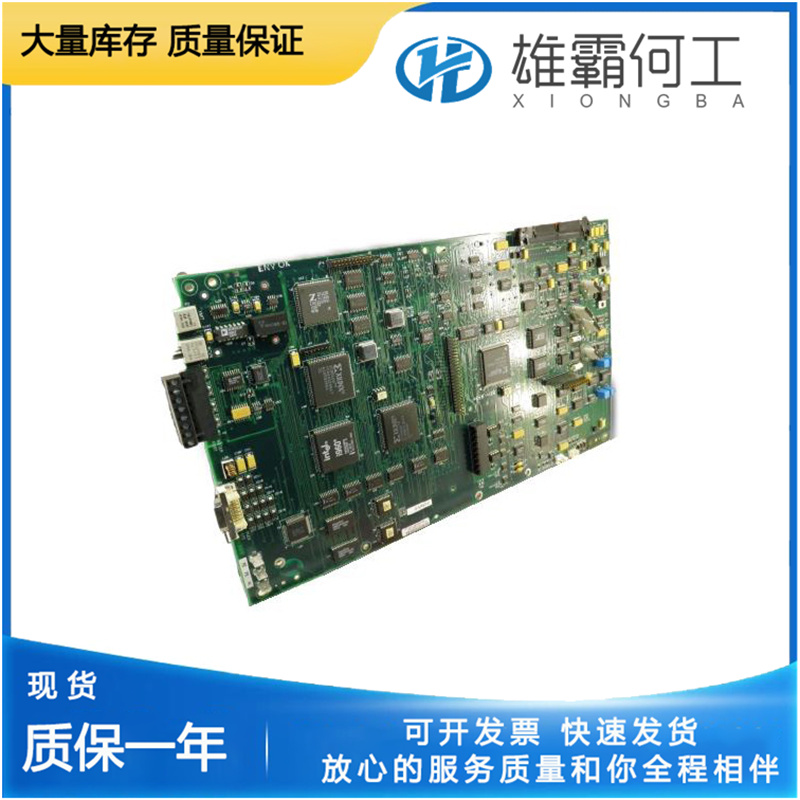

RELANCE 0-58719-32 直流调速板

DCS 系统的日常维护 系统的日常维护是DCS系统稳定高效运行的基础,主要的维护工作有以下几点:

1) 完善DCS系统管理制度。

2) 保证空调设备稳定运行,保证室温变化小于±5℃/h ,避免由于温度、湿度急剧变化导致在系统设备上的凝露。

3) 尽量避免电磁场对系统的干扰,避免移动运行中的操作站、显示器等,避免拉动或碰伤设备连接电缆和通讯电缆等。

4) 注意防尘,现场与控制室合理隔离,并定时清扫,保持清洁,防止粉尘对元件运行及散热产生不良影响;

5) 严禁使用非正版软件和安装与系统无关软件。

6) 做好控制子目录文件的备份,各自控回路的PID 参数、调节器正反作用等系统数据记录工作。

7) 检查控制主机、显示器、鼠标、键盘等硬件是否完好,实时监控工作是否正常。

8) 查看故障诊断画面,是否有故障提示。

9) 系统上电后,通信接头不能与机柜等导电体相碰,互为冗余的通信线、通信接头不能碰在一起,以免烧坏通信网卡。

预防维护 有计划地进行主动性维护,保证系统及元件运行稳定可靠,运行环境良好及时检测更换元器件,消除隐患。每年应利用大修进行一次预防性的维护,以掌握系统运行状态,消除故障隐患。大修期间对DCS 系统应进行彻底的维护,内容包括:

1) 系统冗余测试: 对冗余电源、服务器、控制器、通讯网络进行冗余测试。操作站、控制站停电检修。包括计算机内部、控制站机笼、电源箱等部件的灰尘清理。

2) 系统供电线路检修。并对UPS进行供电能力测试和实施放电操作。

3) 接地系统检修。包括端子检查、对地电阻测试。

4) 现场设备检修。具体做法可参照有关设备说明书。大修后系统维护负责人应确认条件具备方可上电,并应严格遵照上电步骤进行。

1) Improve the DCS system management system.

2) Ensure the stable operation of the air conditioning equipment, ensure that the temperature change is less than ± 5 ℃/h, and avoid condensation on the system equipment due to rapid changes in temperature and humidity.

3) Try to avoid interference from electromagnetic fields on the system, avoid moving operating stations, displays, etc. during operation, and avoid pulling or damaging equipment connection cables and communication cables.

4) Pay attention to dust prevention, properly isolate the site from the control room, and regularly clean and maintain cleanliness to prevent adverse effects of dust on component operation and heat dissipation;

5) It is strictly prohibited to use non genuine software and install software unrelated to the system.

6) Make a backup of the control subdirectory files, and record system data such as PID parameters of each control circuit and the positive and negative effects of the regulator.

7) Check if the control host, monitor, mouse, keyboard, and other hardware are intact, and if real-time monitoring is working properly.

8) Check the fault diagnosis screen for any fault prompts.

9) After the system is powered on, the communication connectors should not collide with conductive bodies such as cabinets, and redundant communication lines and connectors should not collide with each other to avoid burning out the communication network card

Proactive maintenance is carried out in a planned manner to ensure stable and reliable operation of the system and components, a good operating environment, and timely detection and replacement of components to eliminate hidden dangers. Preventive maintenance should be carried out annually through major repairs to grasp the operating status of the system and eliminate potential faults. During the overhaul period, the DCS system should be thoroughly maintained, including:

1) System redundancy testing: Conduct redundancy testing on redundant power supplies, servers, controllers, and communication networks. Power outage maintenance for operation and control stations. Dust cleaning of components such as computer interiors, control station cages, and power boxes.

2) System power supply line maintenance. And conduct power supply capacity testing and discharge operations on UPS.

3) Grounding system maintenance. Including terminal inspection and ground resistance testing.

4) On site equipment maintenance. The specific method can refer to the relevant equipment manual. The person in charge of system maintenance after major repairs should confirm that the conditions are met before powering on, and strictly follow the powering on steps.