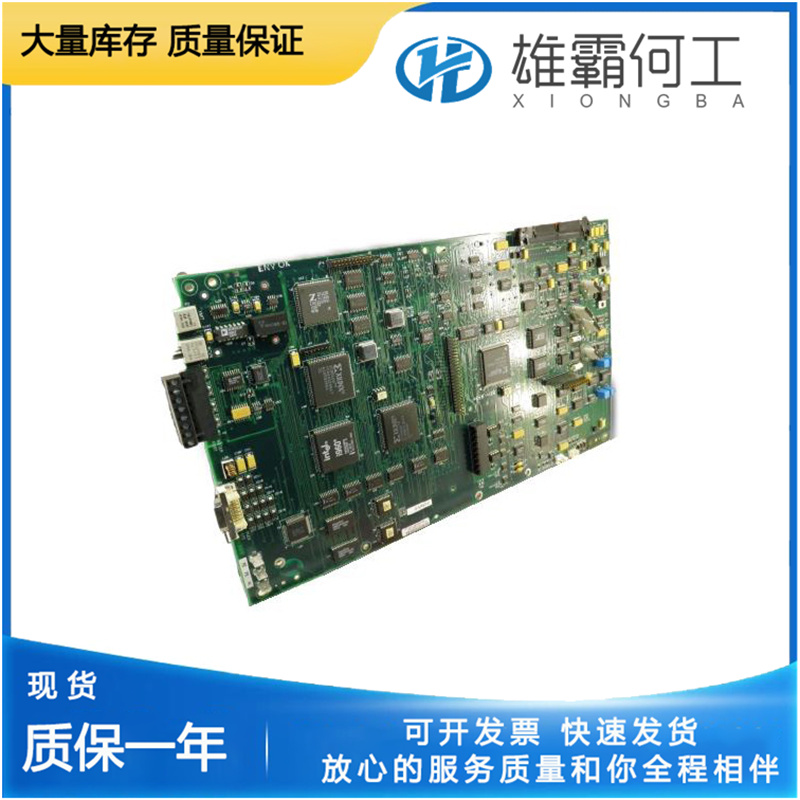

RELANCE 0-60002-6 驱动板电机

DCS在小型火电厂应用中存在的问题

①国产DCS硬件的制造工艺及制造水平离国际水平有较大的差距,硬件的故障率较高;② 由于缺乏切实可行的测试方法和手段。有些DCS性能指标无法进行考核和验收。许多性能指标没有达到规范要求;③由于DCS市场竞争激烈,价格压得很低。DCS供应商在工程设计及应用软件的开发上不可能有很大的投入。在硬件配置上往往并没有体现DCS的分散控制原则。特别是在小型系统中。这种现象尤为明显;④工程设计及应用软件的开发水平也不高。先进的控制软件及控制策略不能推广应用。不利于电厂的经济安全运行;⑤国产检测元件及执行机构的可靠性、准确性往往不能满足DCS控制系统的要求。加大了系统自动调节投入的难度。使得DCS的优势不能完全发挥出来,影响了机组的经济运行;

EcoStruxure混合型DCS(原名PlantStruxure PES)利用工业物联网(IIoT)的强大功能,将您的工厂带向未来。它是一套单一的自动化系统,用于设计、操作和维护整个基础设施,以实现可持续、高效和灵活应对市场的工厂。

特性

1.全系统基于以太网的能效管理架构-透明和标准化的以太网技术可以确保连接线、灵活性、可扩展性和性能

全系统基于以太网的能效

2.强大、可扩展的控制器平台-支持一系列控制器,可以满足不同的过程需求

3.统一环境下的功能整合-整合了在工程设计、运行和维护的统一环境中高效过程管理及其能源使用的一些功能

advantage

1. Centralized hardware and software configuration is unified throughout the entire system, and an engineering system with integrated configuration for on-site equipment

2. Avoiding errors and shortening project time: A single global database and one-time configuration concept eliminate redundant entries and make data available throughout the entire system

Thanks to a pre configured, tested, and validated object template library, asset allocation has been simplified.

4. Simplify device replication by reusing existing object templates

① Automatic detection: Using detection components and display instruments, continuously measure and display the thermal parameters (pressure, temperature, flow rate, etc.) of the boiler, and provide detection signals for automatic regulation and safety protection.

② Automatic adjustment: Automatically adjust the operating parameters of the boiler to meet the requirements of external loads and working fluid parameters, and keep the boiler operating under more economical conditions.

③ Program control: To automate a series of operations such as starting, stopping, and running the boiler. If the system starts, follow the starting sequence of the induced draft fan, blower, and grate.

④ Protection interlock: The system must have functions such as sound and light alarms for overpressure, high water level, and low water level, as well as thermal interlock protection for overpressure shutdown and low water level shutdown. Electrical interlocking protection is to prevent accidents caused by operational errors during equipment startup and shutdown processes.