VM600 IOCN PNR200-566-000-112的操作指南

VM600 IOCN PNR200-566-000-112 Operation Guide

(Vibro-Meter Mechanical Protection System Module)

1. Physical Installation

Mounting

Secure to DIN rail (EN 60715 standard) using torque-controlled fasteners (0.6 Nm ±0.1 Nm)26. Ensure lateral shift ≤0.5mm for connector alignment2.

Environmental Requirements

Operating range: -25°C to +55°C; humidity ≤95% non-condensing26. Requires IP54 enclosure for harsh environments (e.g., turbine nacelles)5.

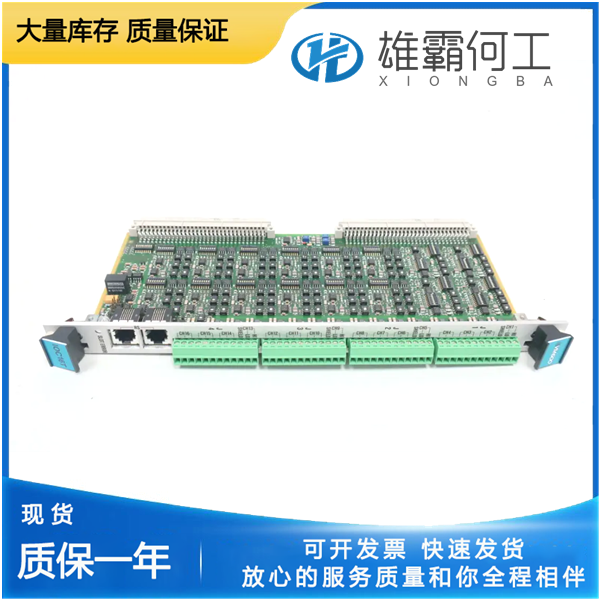

2. Electrical Wiring

plaintextCopy Code[Terminal Configuration]

• Safety Inputs (S11-S12): PNP/NPN configurable, 18-30V DC

• Dynamic Signal Inputs: IEPE-compatible (4-20mA)

• Ethernet Port: RJ45 (10/100BASE-T)

[Critical Practices]

→ Shielded twisted pairs for analog signals :ml-citation{ref="1,7" data="citationList"}

→ Ground shield at single point only :ml-citation{ref="4" data="citationList"}

→ Separation ≥100mm from power cables :ml-citation{ref="2" data="citationList"}3. Network Integration

Protocol Setup

Configure via VM600 CPUM software:iniCopy Code[COMM_Protocol] Type=PROFINET ; Alternatives: PROFIBUS, Ethernet/IP Update_Rate=8ms ; Min cycle time Node_ID=0x20 ; Unique address

Supports real-time data exchange with PLCs (e.g., Siemens S7-1500)14.

Diagnostic Verification

4. Operational Workflow

Power-Up Sequence

- Apply 24V DC (19.2-30V range)2

- Wait for SYSTEM READY LED (green steady)6

- Initialize sensors via VM600 ConfigTool1

Runtime Monitoring

- Track vibration thresholds (API 670 compliance)4

- Use MODBUS register 40012 for real-time RPM data1

- Enable auto-triggering for >5% overspeed events3

Safety Interlocks

textCopy CodeEmergency Stop Logic: S11──┤ESTOP├──S12 → Output de-energizes within 50ms

Test monthly via forced fault simulation27.

5. Maintenance & Troubleshooting

Preventive Actions

- Annual contact inspection (mechanical life: 10⁷ ops)6

- Clean air vents quarterly (ΔT >10°C indicates clogging)5

Common Faults